Eins is particularly proud of its quick E.O.A.T. change systems, which are suitable for every kind of injection moulding production, from 40 ton to 5000 ton-injection moulding machines.

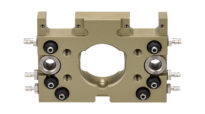

The E.O.A.T. change system can be either manual or automatic. Tool changers are available in two materials: stainless steel and A-2024 superduralumin, a lightweight yet strong material particularly popular within the aircraft industry.

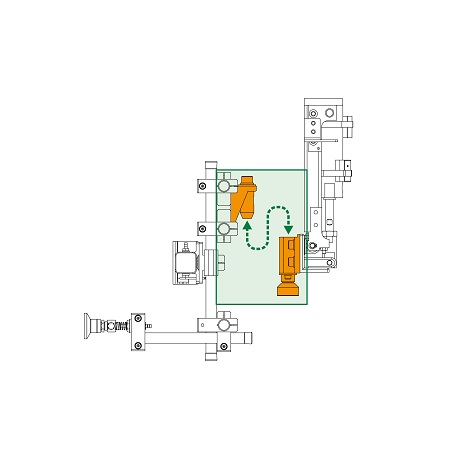

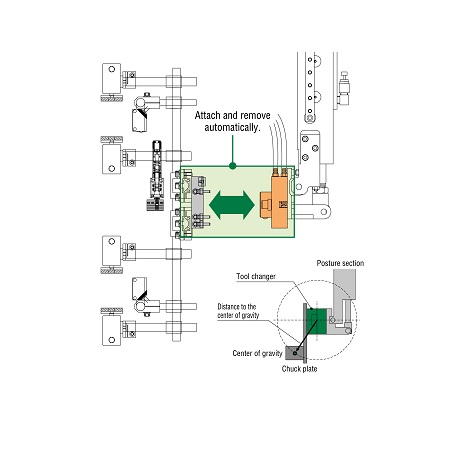

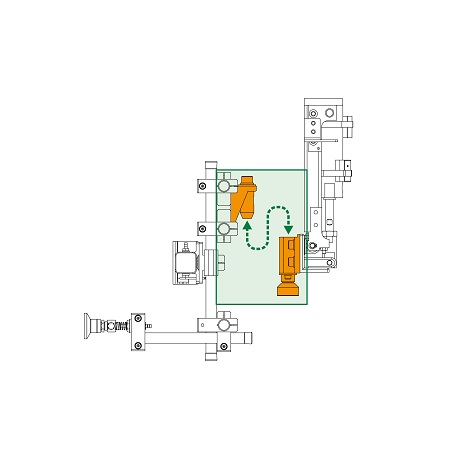

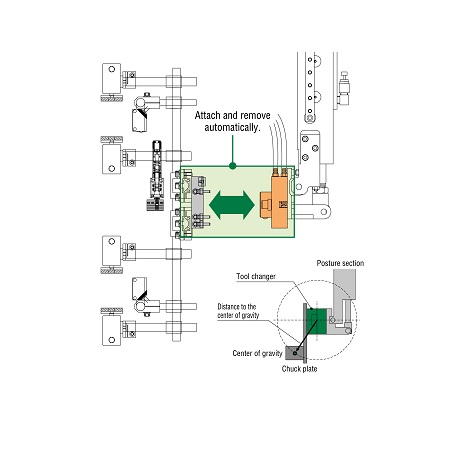

Manual chuck changers allow to change the E.O.A.T. simply by tightening one single screw, while chuck automatic change is effective for the reduction of setup change time, different connection of air and electrical components, as well as location accuracy for end of arm tooling exchanges. The tool station can be either a tree-type floor stand or attached to the traverse axis (NT type). Magnet chuck hangers use the magnetic power of neodymium to hold the end of arm tooling.

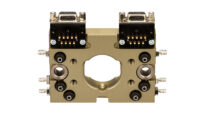

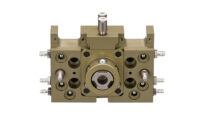

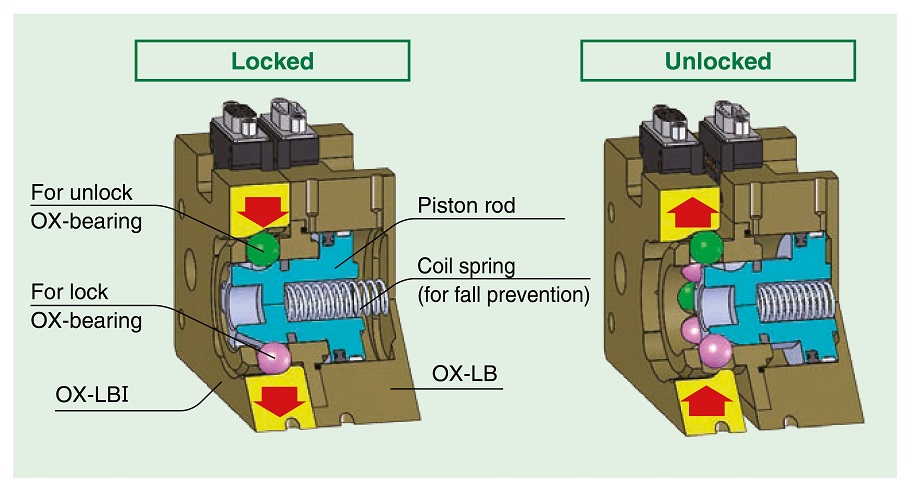

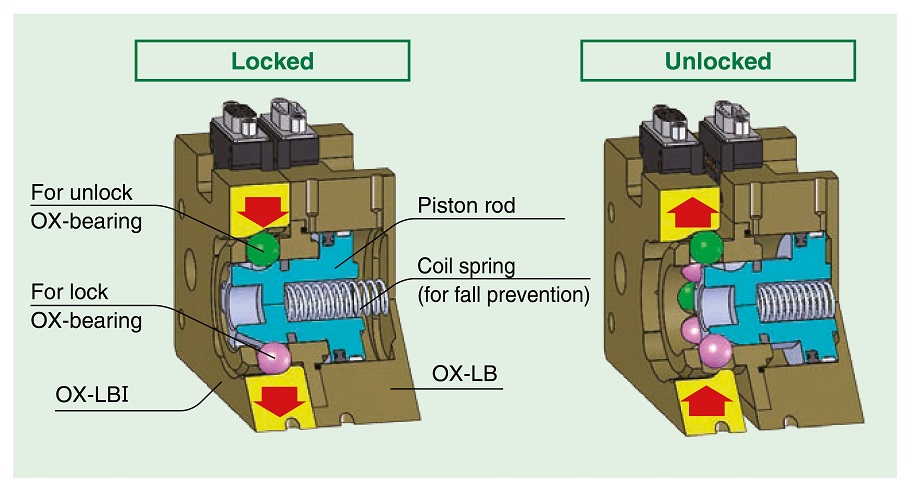

Our OX series tool changers are available in many models, both for Cartesian and six-axes robots. Locking and unlocking are performed through metal spheres running on special bearings, thanks to a system patented by Star Group (EP 1 970 170). Anti-fall system prevents the chuck side from falling even in case of air supply interruption, while the air locking systems closes air ways so that tool changers do not suffer any air loss. The loadable weight spans from 3 to 80 kilograms, making OX series applicable to every need.

OA and OX series tool changers come with the widest variety of accessories. From D-SUB connector cables to manual air valves to bearing metal spheres, you can find here everything you may need for your tool changers. We have recently introduced also wireless connectors, which can be used in places with a high presence of dust or moisture: with their contactless design, they can be used on both Cartesian and six-axes robots.

Eins is particularly proud of its quick E.O.A.T. change systems, which are suitable for every kind of injection moulding production, from 40 ton to 5000 ton-injection moulding machines.

The E.O.A.T. change system can be either manual or automatic. Tool changers are available in two materials: stainless steel and A-2024 superduralumin, a lightweight yet strong material particularly popular within the aircraft industry.

Manual chuck changers allow to change the E.O.A.T. simply by tightening one single screw, while chuck automatic change is effective for the reduction of setup change time, different connection of air and electrical components, as well as location accuracy for end of arm tooling exchanges. The tool station can be either a tree-type floor stand or attached to the traverse axis (NT type). Magnet chuck hangers use the magnetic power of neodymium to hold the end of arm tooling.

Our OX series tool changers are available in many models, both for Cartesian and six-axes robots. Locking and unlocking are performed through metal spheres running on special bearings, thanks to a system patented by Star Group (EP 1 970 170). Anti-fall system prevents the chuck side from falling even in case of air supply interruption, while the air locking systems closes air ways so that tool changers do not suffer any air loss. The loadable weight spans from 3 to 80 kilograms, making OX series applicable to every need.

OA and OX series tool changers come with the widest variety of accessories. From D-SUB connector cables to manual air valves to bearing metal spheres, you can find here everything you may need for your tool changers. We have recently introduced also wireless connectors, which can be used in places with a high presence of dust or moisture: with their contactless design, they can be used on both Cartesian and six-axes robots.