In this section you can find all the products of our catalogue which employ vacuum technology for the correct chucking of the moulded products.

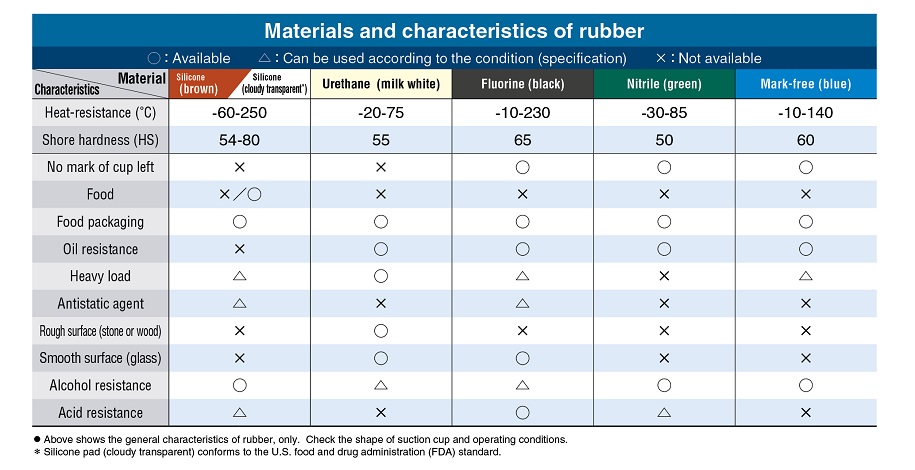

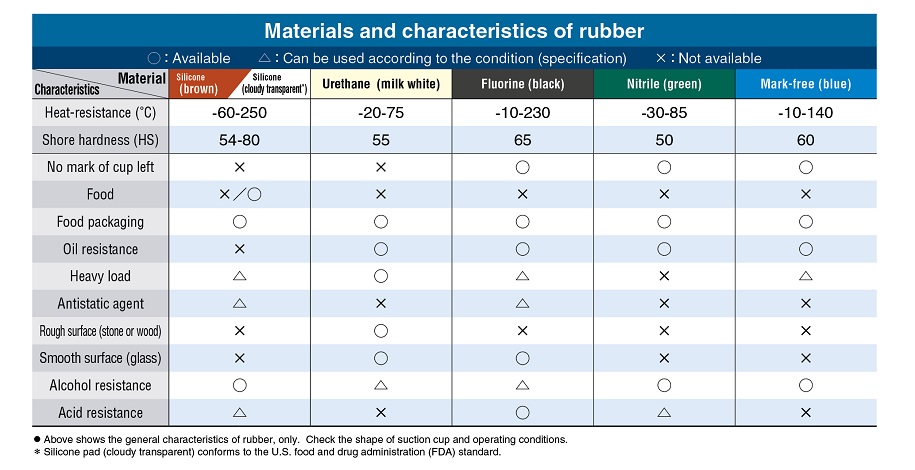

The basic use can be exemplified by suction cups and suction stems. Eins has one of the largest ranges of suction cups, with many variations in their shape, diameter, material, folds etcetera. Please refer to the following table to understand in a glimpse the different usages of our cups materials. We can also offer cups for metal sheets and cups with a spongy surface, in order to perfectly chuck products with uneven surfaces. In case your cup has been damaged or worn out, we can also provide you with the correspondent replacement.

Suction stems come in many strokes and always guarantee a secure suction. The cup fixing system is embedded. Non-rotating or adjustable angle stems are also available.

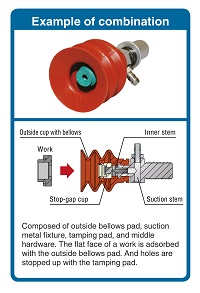

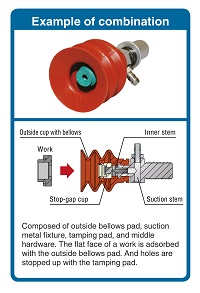

Pad in pad is the perfect solutions when you have problems with pierced products, such as food containers, caps and inner stoppers of cosmetic containers, small gears, metal nuts etcetera. Composed of outside bellows cup, suction metal fixture, tamping cup and middle hardware, the flat face of the product is absorbed with the outside bellows pad. Holes are then stopped thanks to the inner tamping pad. Pad in pad is applicable to mini or small suction stems. This solution helps preventing dust and stains deriving from automatic drop from the mould, as well as reducing inspection times: in fact, only sampling inspection is sufficient.

Pad in pad is the perfect solutions when you have problems with pierced products, such as food containers, caps and inner stoppers of cosmetic containers, small gears, metal nuts etcetera. Composed of outside bellows cup, suction metal fixture, tamping cup and middle hardware, the flat face of the product is absorbed with the outside bellows pad. Holes are then stopped thanks to the inner tamping pad. Pad in pad is applicable to mini or small suction stems. This solution helps preventing dust and stains deriving from automatic drop from the mould, as well as reducing inspection times: in fact, only sampling inspection is sufficient.

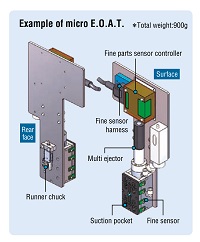

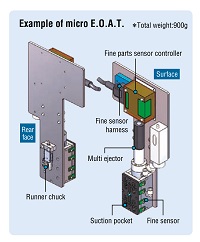

Here you can also find our Micro Mould E.O.A.T. application, which allows to separate each cavity product of micro moulding processes carried out by small tonnage injection moulding machines (20 tons or less). A compact and high-performance multi ejector is used, alongside a fine sensor unit in order to check the correct suction of the micro workpieces. A micro parts sensor controller is also available: it is possible to detect up to 32 points, confirming the input condition of the sensor through a LED monitor. It is also possible to choose between NPN or PNP input, as well as between AND and OR output.

In this section you can find all the products of our catalogue which employ vacuum technology for the correct chucking of the moulded products.

The basic use can be exemplified by suction cups and suction stems. Eins has one of the largest ranges of suction cups, with many variations in their shape, diameter, material, folds etcetera. Please refer to the following table to understand in a glimpse the different usages of our cups materials. We can also offer cups for metal sheets and cups with a spongy surface, in order to perfectly chuck products with uneven surfaces. In case your cup has been damaged or worn out, we can also provide you with the correspondent replacement.

Suction stems come in many strokes and always guarantee a secure suction. The cup fixing system is embedded. Non-rotating or adjustable angle stems are also available.

Pad in pad is the perfect solutions when you have problems with pierced products, such as food containers, caps and inner stoppers of cosmetic containers, small gears, metal nuts etcetera. Composed of outside bellows cup, suction metal fixture, tamping cup and middle hardware, the flat face of the product is absorbed with the outside bellows pad. Holes are then stopped thanks to the inner tamping pad. Pad in pad is applicable to mini or small suction stems. This solution helps preventing dust and stains deriving from automatic drop from the mould, as well as reducing inspection times: in fact, only sampling inspection is sufficient.

Pad in pad is the perfect solutions when you have problems with pierced products, such as food containers, caps and inner stoppers of cosmetic containers, small gears, metal nuts etcetera. Composed of outside bellows cup, suction metal fixture, tamping cup and middle hardware, the flat face of the product is absorbed with the outside bellows pad. Holes are then stopped thanks to the inner tamping pad. Pad in pad is applicable to mini or small suction stems. This solution helps preventing dust and stains deriving from automatic drop from the mould, as well as reducing inspection times: in fact, only sampling inspection is sufficient.

Here you can also find our Micro Mould E.O.A.T. application, which allows to separate each cavity product of micro moulding processes carried out by small tonnage injection moulding machines (20 tons or less). A compact and high-performance multi ejector is used, alongside a fine sensor unit in order to check the correct suction of the micro workpieces. A micro parts sensor controller is also available: it is possible to detect up to 32 points, confirming the input condition of the sensor through a LED monitor. It is also possible to choose between NPN or PNP input, as well as between AND and OR output.